WL+JR

Features & Benefits

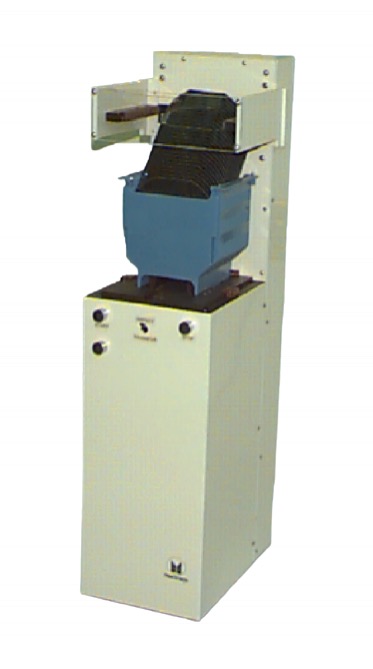

- The Wafer Inspection system will lift the wafers to a predetermined point every time for inspection. If the operator needs the wafers higher. Press the start button the system will raise the wafers until the operator presses the pause button. The stop button will return the wafers to the carrier.

- The Junior Series III transfers wafers between one 25-slot carrier and one 25-slot Quartz boat. Carriers/boats can be plastic, Teflon Quartz, Silicon Carbide, Polysilicon and metal boats. With the push of a button, the machine transfers wafers safely and automatically.

- The series III machine is totally air operated, therefore it is cost effective. Its simple design eliminates extensive R&M training.

- Flat alignment is preserved during transfer.

- Pressure sensors are used for both personal safety and machine safety by inhibiting machine operation.

- Retainers default to closed position to prevent dropping wafers in the event of air pressure loss.

- Aluminum parts are hard black anodized for corrosion resistance.

- Wafer contact is minimized to ensure maximum cleanliness for critical diffusion processes, improving yields and productivity.

- Uptime will exceed 99.25%.

- MTBF (mean time between failure): 2,500 hours

- MTBA (mean time between assist): 1,000 hours

- MTTR (mean time to repair): 1 hour

Options

- Recessed mounting

- Vespel package for high temperature applications

- Stainless steel covers.

- Hot boat sensor